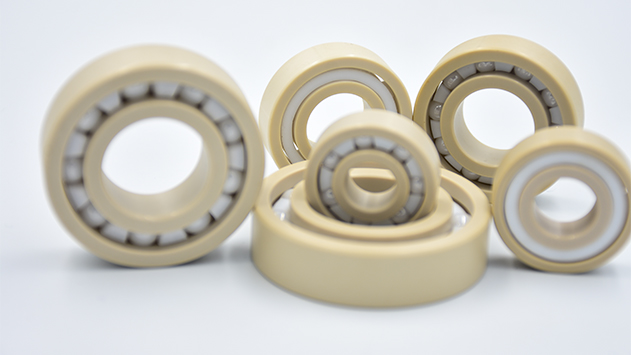

High quality plastic bearings

Plastic sliding bearings can not only be made into the shape of shaft sleeves, but can also be made into plastic linear sliding bearings, but the premise is that the material made must undergo self-lubricating improvement to improve its comprehensive wear resistance; For example, the common plastic linear bearings in the current market are made of engineering plastics modified with lubricants and reinforced fibers, which have excellent wear resistance.

Product Description

Quality assurance

Customized production

Plastic bearings are sliding bearings made of polymers or with polymer liners. Currently, plastic bearings are generally divided into plastic rolling bearings and plastic sliding bearings. Due to the numerous advantages of plastic sliding bearings over metal sliding bearings, the production of plastic bearings is currently expanding, and the usage of plastic bearings is also constantly extending. From fitness equipment to office equipment, as well as the automotive industry, plastic bearings are used. Currently, there are no cars that do not use plastic bearings on the road.

Basic information

Classification: Plastic rolling bearings and plastic sliding bearings

Application: Suitable for electromechanical equipment, fitness equipment, etc

Features: Good corrosiveness, high mechanical strength

The working principle of plastic rolling bearings and plastic sliding bearings can be distinguished by their names. The friction that occurs during the operation of plastic rolling bearings is rolling friction, while the friction that occurs during the operation of plastic sliding bearings is sliding friction; The magnitude of rolling friction force mainly depends on manufacturing accuracy; The magnitude of friction force in plastic sliding bearings mainly depends on the material of the sliding surface of the bearing.

Plastic sliding bearings generally have self-lubricating functions on their working surfaces; Plastic sliding bearings are generally made of engineering plastics with good performance; Professional manufacturers generally have self-lubricating modification technology for engineering plastics. They use fibers, special lubricants, glass beads, and other materials to enhance the self-lubricating properties of engineering plastics, and then use modified plastics to process them into self-lubricating plastic bearings through injection molding.

The characteristics of plastic sliding bearings:

1. Plastic bearings are made entirely of lubricating materials, with a long service life;

2. Plastic bearings will not rust and are corrosion-resistant during use, while metal bearings are prone to rust and cannot be used in chemical liquids;

3. Plastic bearings are lighter in weight than metals, which is more suitable for modern lightweight design trends;

4. The manufacturing cost of plastic bearings is lower than that of metals; Plastic bearings are processed by injection molding and are more suitable for mass production;

5. Plastic bearings have no noise during operation and have a certain vibration absorption function;

6. Plastic sliding bearings are suitable for high and low temperature operation -200 to+250 degrees;