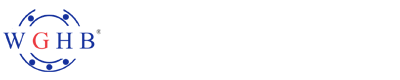

Sealed spherical roller bearings

The sealed bearing has been injected with extreme pressure lubricating grease. Before installing the sealed bearing, it must not be cleaned or heated beyond 80 ℃.

Sealed bearings allow for an angle error of less than 0.5 degrees between the bearing and the bearing seat, which does not affect the sealing function within this reference value.

Product Description

High load carrying capacity

Long service life

Low friction

Sealing ring self-aligning roller bearing generally refers to the installation of sealing rings on both end faces of the bearing. The design of the bearing is mainly based on the C-shaped structure of the double row self-aligning roller bearing, with the outer ring being a concave spherical raceway and the inner ring being two concave arc-shaped spherical raceways without outer and outer retaining edges. There is a set of symmetrical spherical drum shaped rollers, stamped with C-shaped steel cage, and the window hole is pressed and sloped to lock the roller arc surface. It is equipped with a powder metallurgy intermediate retaining ring, and the middle part of the outer ring is processed with three lubricating oil grooves and oil holes.

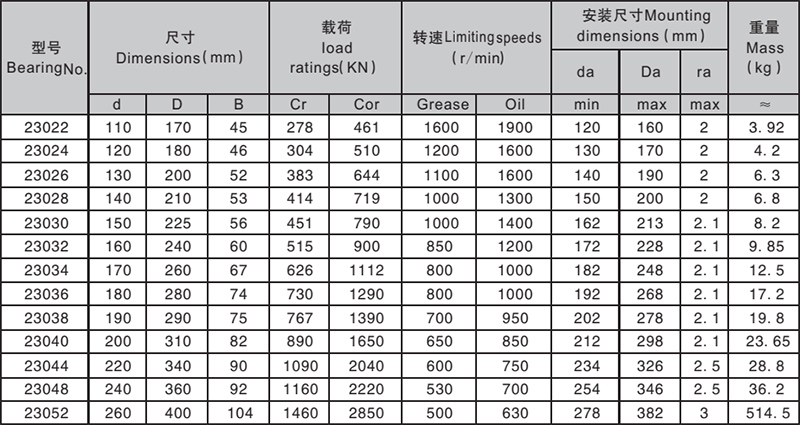

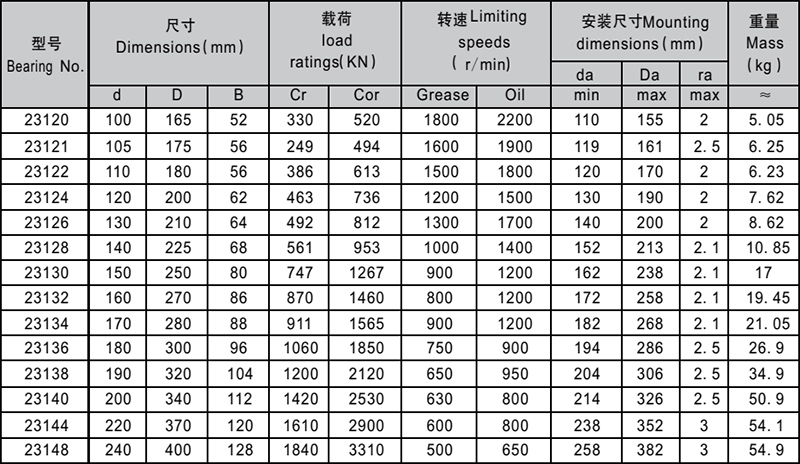

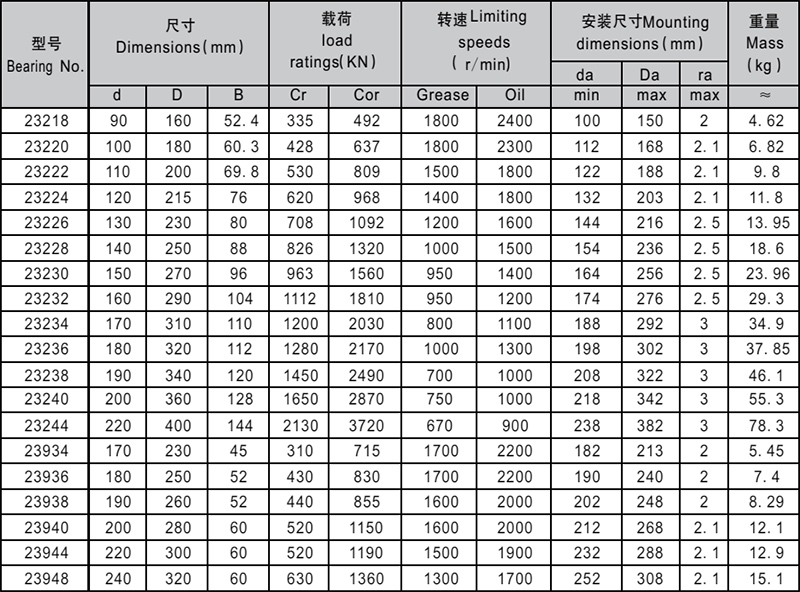

Due to the need to install sealing rings, the width of BS2-22 and BS2-23 series sealed bearings should be appropriately widened, and the external dimensions of other bearings are completely the same. The outer ring has a sealing groove, and the edge of the inner ring raceway has a slope. The outer diameter of the sealing ring is fixed on the outer ring, and the inner lip forms a contact seal with the inner ring slope. The main function of this bearing is similar to that of an open type self-aligning roller bearing, but it is more suitable for situations with harsh working conditions and difficult maintenance.

Sealed self-aligning roller bearings are divided into cylindrical holes and tapered holes (suffix code K, taper 1:12, suffix code K30, taper 1:30).The sealing ring is generally made of nitrile rubber with a suffix of 2CS. When paired with high-temperature bearings, fluororubber with a suffix of 2CS2 is used.

The sealed bearing has been injected with extreme pressure lubricating grease. Before installing the sealed bearing, it must not be cleaned or heated beyond 80 ℃.Sealed bearings allow for an angle error of less than 0.5 degrees between the bearing and the bearing seat, which does not affect the sealing function within this reference value.

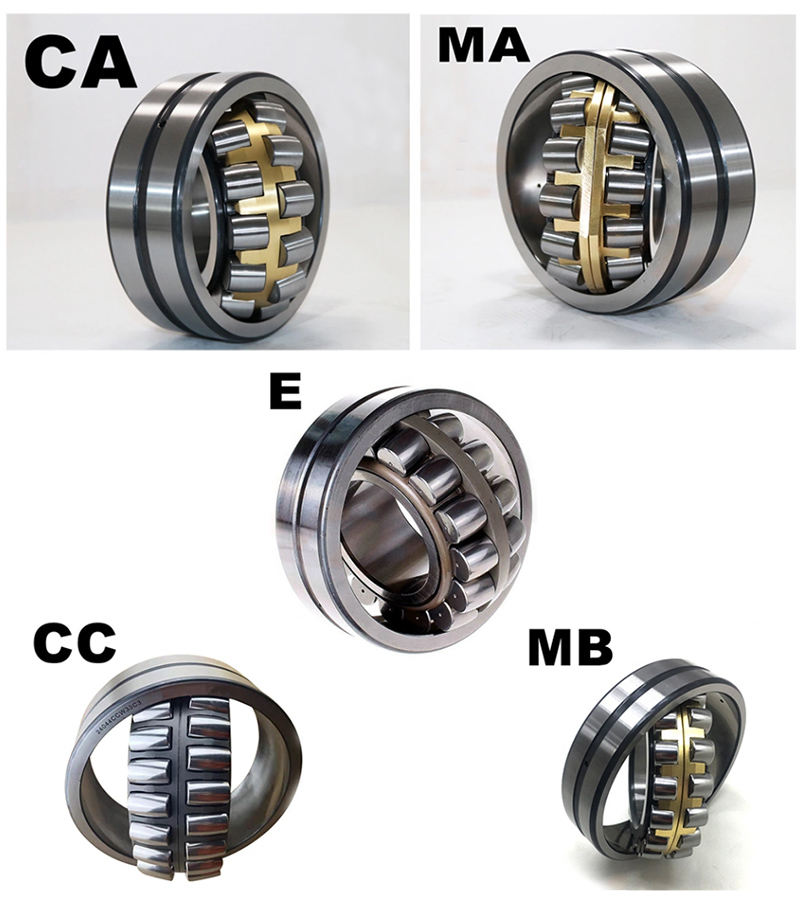

Structure:

Internal Structure and Retainer Material Variation

C: Symmetrical roller, Stamped Steel retainer

CA: Symmetrical roller, one-pice brass cage

CTN1: Symmetrical roller, nylon cage

E: Third generation design. improved stress distribution; offer much longer service life than normal designs

Q: Bronze cage

MB: Symmetrical roller,Two-pice brass cage

EM: Symmetrical roller, Special alloy Integral cage

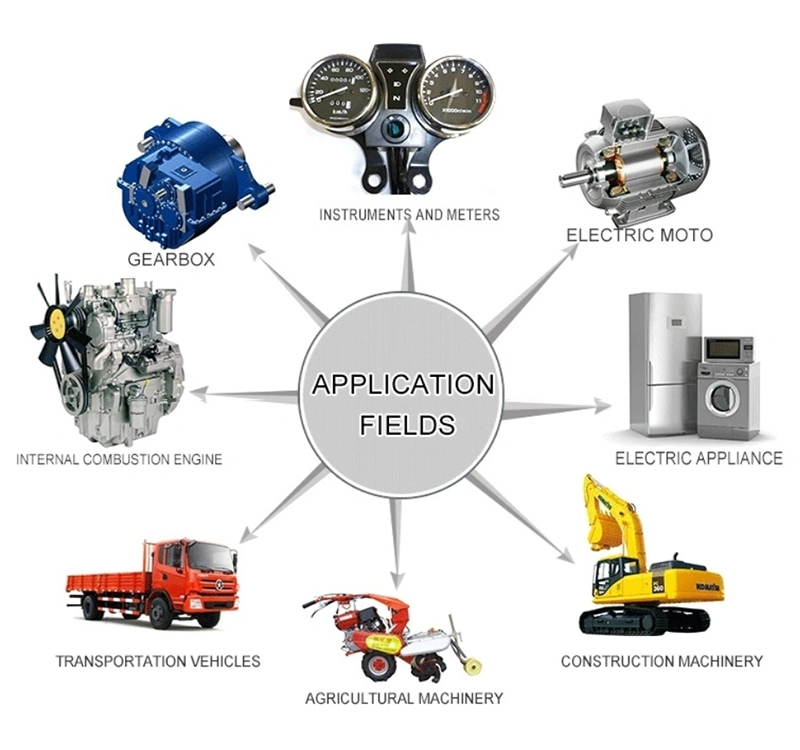

Our products with high precision and low noise, are widely used in metallurgy, mining,petroleum,chemical,coal, cement, paper,wind power, heavy machinery, port machinery and other industries. The company has independent import and export management rights. The products are sold all over the world, exported to more than fifty countries and regions such as South America,Western Europe, Southeast Asia, Central Asia, Africa and Australia.

The company always takes "solution, creation, value" as business philosophy, providing excellent bearing solutions for domestic and foreign customers. WGHB Bearings has passed ISO9001:2008 and ISO14001:2004. Through the implementation of strict quality standards, taking rigorous quality control measures to improve product quality and service quality, WGHB Bearings provides high quality products and services to consumers around the world.

Welcome all your OEM and ODM order. Your spefic purchase needs of selecting current product from our catalogue or seeking engineering assistance for your application will be directly submit to our customer service center, we will answer you ASAP.