Linear flange bearing

The advantages include low friction resistance, high precision, smooth motion, strong bearing capacity, and long service life. Small outer diameter steel balls are used to obtain low friction torque, high rigidity, and good rotary precision. The use of hollow shafts ensures light weight and wiring space.

Product Description

Quality assurance

Customized production

The linear flange bearing is a kind of linear motion system, which is used in combination with the cylindrical shaft for unlimited stroke. Since the bearing ball and the shaft are in point contact, the used load is small. The steel ball rotates with extremely small friction resistance, so that high-precision smooth motion can be obtained. It is mainly used in various industrial equipment, small rotary motors, office equipment, and micro-motor soft drives. It is widely used in fields such as machine tools, automated equipment, electronic equipment, medical equipment, and printing equipment.

Its structure includes parts such as the outer ring, the inner ring, the steel balls, the retainer, and the seal. Among them, the outer ring and the inner ring are the main components of the bearing, and they achieve relative movement through the rolling of the rolling elements (steel balls). The retainer is used to maintain the position and spacing of the rolling elements to prevent the rolling elements from colliding and rubbing against each other. The seal is used to prevent the leakage of the lubricant and the entry of external dust and impurities into the bearing interior, thus protecting the normal operation of the bearing.

Advantages of linear flange bearings:

The advantages include low friction resistance, high precision, smooth motion, strong bearing capacity, and long service life. Small outer diameter steel balls are used to obtain low friction torque, high rigidity, and good rotary precision. The use of hollow shafts ensures light weight and wiring space.

Characteristics of linear flange bearings:

The most significant feature is to combine the flange with the bearing into one. When one end of the shaft has no connecting parts and needs to be fixed on a plane such as a plate or wall, the flange bearing exhibits its advantage. In super-small diameter micro bearings, it can be divided into ZZ steel plate bearing dust cover series, RS rubber bearing seal ring series, Teflon bearing seal ring series, flange plate series, stainless steel series, ceramic ball series, etc. Micro ball bearings have a wide range of uses. It is suitable for products that require high-speed rotation, low friction torque, low vibration, and low noise.

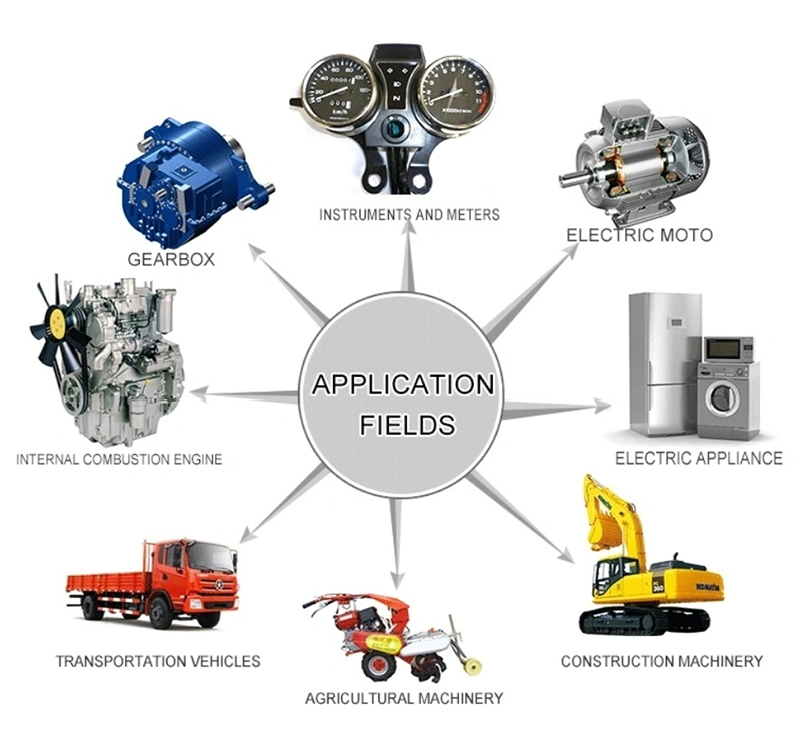

Main uses:

Flange bearings are suitable for various industrial equipment, small rotary motors, office equipment, micro-motor soft drives, pressure rotors, dental drill bits, hard disk motors, stepper motors, video tape recorders magnetic drums, toy models, fans, pulleys, rollers, transmission equipment, entertainment equipment, robots, medical equipment, office equipment, testing instruments, speed reduction and variable speed devices, motor optics, imaging equipment, card readers, electromechanical, precision machinery, electric tools, and toys, etc.

Precautions:

1. When installing, pay attention to keeping the bearing clean and dry to avoid dust and impurities from entering the bearing interior.

2. When installing, pay attention to maintaining the correct position and direction of the bearing to avoid bearing damage due to incorrect installation.

3. When using, pay attention to maintaining the lubrication of the bearing to avoid bearing damage due to lack of lubrication.

4. When using, pay attention to avoiding the bearing from being subjected to excessive loads and impacts to avoid bearing damage due to overload.