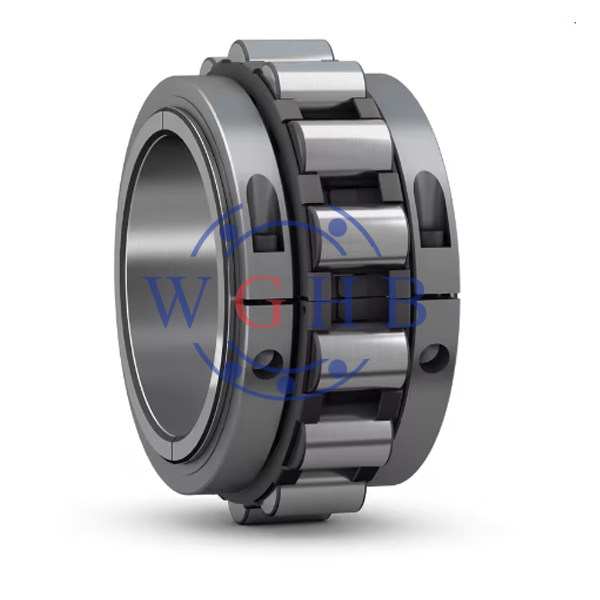

Split bearing

Split bearing units can be disassembled into smaller components, simplifying lifting and handling tasks, making installation or replacement simple, even in the most narrow and inaccessible conditions. Pre-set clearance, so no on-site adjustment or professional installation tools are required. The following introduces the split bearing to you in detail from the advantages, functions, classification, selection, and maintenance of the split bearing respectively.

Product Description

Customized production

Special application bearings

Split bearing units can be disassembled into smaller components, simplifying lifting and handling tasks, making installation or replacement simple, even in the most narrow and inaccessible conditions. Pre-set clearance, so no on-site adjustment or professional installation tools are required. The following introduces the split bearing to you in detail from the advantages, functions, classification, selection, and maintenance of the split bearing respectively.

The split bearing is a component produced through special process design on the basis of the integral bearing. It has small working resistance, smooth operation, and a working temperature that can reach 180 degrees Celsius, which is very suitable for use in places with low speed, heavy load, large impact force, and poor sealing performance. Its greatest advantage is that it can be conveniently installed and disassembled, which can save a lot of time and reduce production costs.

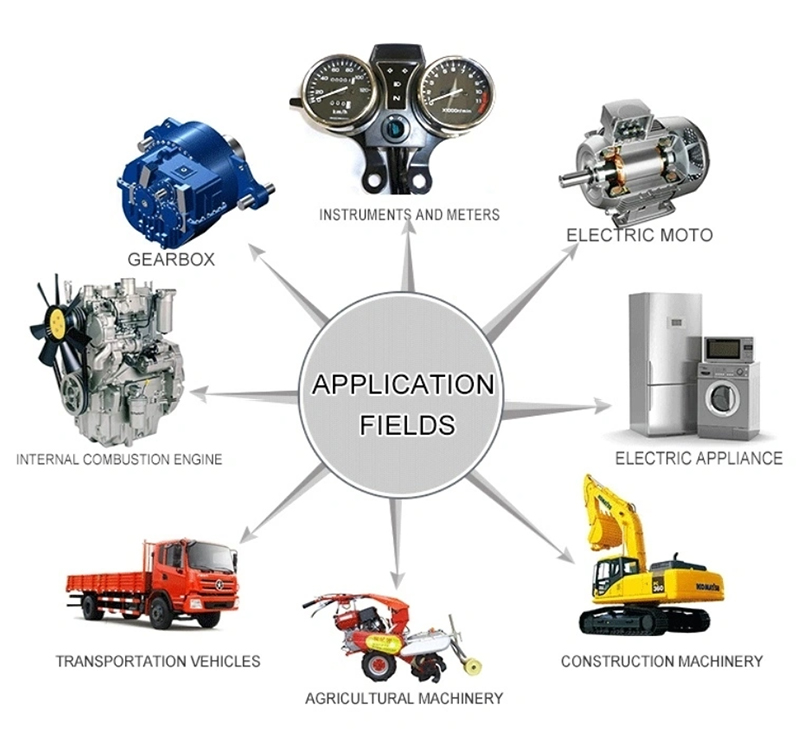

Split bearings are suitable for all industrial fields and are mainly used in difficult-to-remove places such as converter support, various large-scale conveying equipment, continuous casting roll support, elevators and conveyors, and paper-making machinery. When using split bearings, it is necessary to pay attention to their operating conditions. If it is found that the operation is not flexible, it is necessary to analyze and find solutions according to specific circumstances.

The advantages of split bearings:

With small working resistance, smooth operation, and a working temperature up to 180 degrees Celsius, they are very suitable for use in places with low speed, heavy load, large impact force, and poor sealing performance. Its advantage is that the bearing can be conveniently installed and disassembled, which can save a lot of time and reduce production costs.

The function of split bearings:

The function of this kind of part is very simple but also very important. Many times, people call it "the joint of the machine". In the bearing inside the machine and large parts, if they want to perform flexible rotation, it relies on these split bearings to provide support, so that the machine can perform flexible steering and operation.

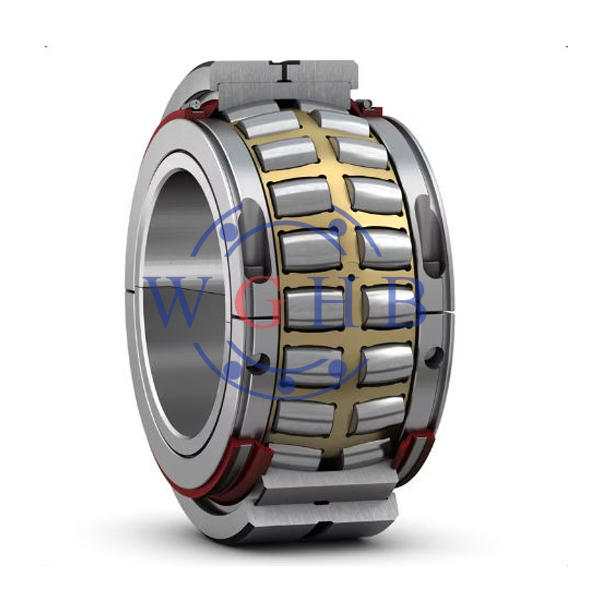

The classification of split bearings:

Now the split bearing has become a very rich big family. In this big family, it includes hundreds of different support models, such as single-layer, double-layer, triple-layer, and four-layer... There are ball-type rotation, touch-type rotation, and roller-type rotation, which are dazzling and have a wide selection.

The selection of split bearings:

In the selection of split bearings, what everyone must pay attention to is the material used by this support itself, because it needs to be rubbed and operated at all times, and there are high requirements for the hardness and wear resistance of the material, and it is also necessary to pay attention to the specification of the entire part in order to be better used.

Maintenance of split bearings:

Try not to let the split bearing come into contact with water (the skateboard surface is the same), when you hear the sound of metal friction, it may be that there is no oil. It is necessary to maintain it in a timely manner, so as to increase your service life. Try not to remove the outer sealing cover, although it is very fast to use it that way, but the disadvantages caused are very many.

Jinan Shengbang Bearing Co., Ltd. is a modern precision bearing manufacturer integrating R&D(research and development), production and sales. Our company has advanced production equipment, fully adopting advanced production technology and modern testing equipment to improve the precision performance of our products. The company promotes the"WGHB" brand, specializing in the production of deep groove ball bearings, taper roller bearings, spherical roller bearings, cylindrical roller bearings, pillow block bearings and other special bearings and non-standard bearings.

Our products with high precision and low noise, are widely used in metallurgy, mining,petroleum,chemical,coal, cement, paper,wind power, heavy machinery, port machinery and other industries. The company has independent import and export management rights. The products are sold all over the world, exported to more than fifty countries and regions such as South America,Western Europe, Southeast Asia, Central Asia, Africa and Australia.

The company always takes "solution, creation, value" as business philosophy, providing excellent bearing solutions for domestic and foreign customers. WGHB Bearings has passed ISO9001:2008 and ISO14001:2004. Through the implementation of strict quality standards, taking rigorous quality control measures to improve product quality and service quality, WGHB Bearings provides high quality products and services to consumers around the world.

Welcome all your OEM and ODM order. Your spefic purchase needs of selecting current product from our catalogue or seeking engineering assistance for your application will be directly submit to our customer service center, we will answer you ASAP.