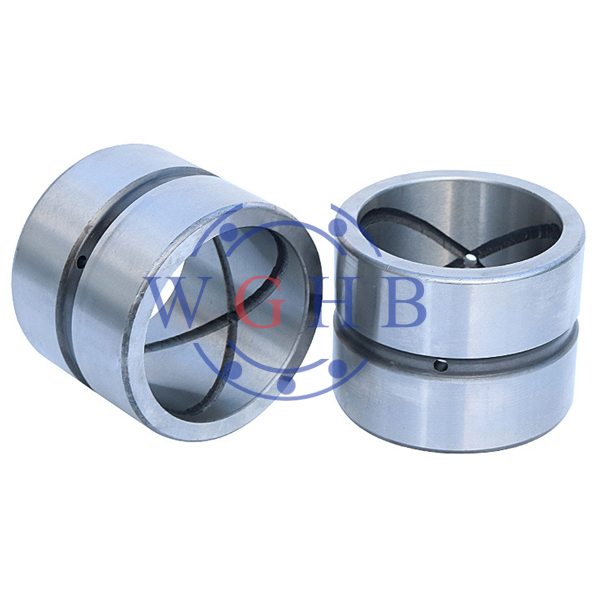

Excavator Bearing

The bearing of the excavator is one of the important components of the excavator, which mainly plays the role of support and reducing friction, so that the various components of the excavator can operate smoothly. The bearings in different parts have different functions, such as the slewing bearing can allow the excavator to achieve the slewing action, while the drive wheel bearing ensures the normal rotation of the drive wheel.

Product Description

Customized production of non-standard bearings and special bearings

Machine tool spindle

The bearing of the excavator is one of the important components of the excavator, which mainly plays the role of support and reducing friction, so that the various components of the excavator can operate smoothly. The bearings in different parts have different functions, such as the slewing bearing can allow the excavator to achieve the slewing action, while the drive wheel bearing ensures the normal rotation of the drive wheel.

The bearings of the excavator include: the bearing for the excavator to walk, the bearing for the excavator to rotate, the needle roller bearing of the excavator, the bearing of the excavator gearbox, the bearing of the excavator walking motor, the bearing for the excavator to walk and drive, the joint bearing of the excavator, the bearing for the excavator to rotate and support, and the British non-standard bearing used on the excavator.

The large bearing of the excavator walking reducer, also known as the side reduction bearing or gearbox bearing, is mainly applied to the walking reducer of the crawler type excavator. The main categories are single-row angular contact ball bearings, double-row angular contact ball bearings, and tapered roller bearings.

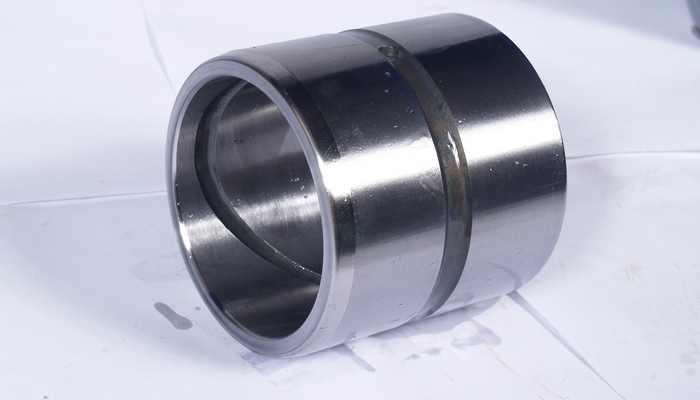

When the excavator is working, the inner ring of the bearing rotates together with the shaft, and the outer ring is fixed on the body. The rolling elements roll between the inner and outer rings, converting the rotary motion of the shaft into smooth rotation, while bearing forces from all directions to ensure the normal operation of each component of the excavator. When selecting the bearing of the excavator, it is necessary to consider factors such as its bearing capacity, wear resistance, and sealing performance to ensure that it can operate stably in a harsh working environment.

The installation and disassembly methods of the bearing of the excavator should be determined according to the structure, size, and the fitting nature with the components of the bearing of the excavator. The pressure for installation and disassembly should be directly applied to the end face of the tight-fitting bearing retainer ring, and the pressure cannot be transmitted through the rolling elements of the bearing of the excavator, because this will cause indentations on the working surface of the bearing of the excavator, which will affect the normal operation of the bearing of the excavator, and even cause damage to the bearing of the excavator. The cage, seal ring, dust cover and other parts of the bearing of the excavator are easily deformed, and the pressure for installing or disassembling the bearing of the excavator cannot be applied to these parts.