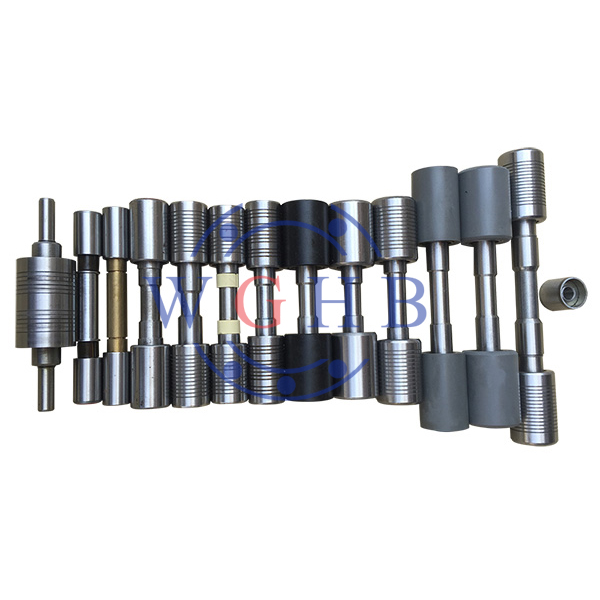

Textile machine bearing

Textile machine bearings are an important component in textile machinery and equipment, which are mainly used to support the mechanical rotating body and reduce the friction coefficient during its motion process. Textile machine bearings have good wear resistance and fatigue resistance to ensure the efficient operation of the textile machine.

Product Description

Quality assurance

Customized production

Textile machine bearings are an important component in textile machinery and equipment, which are mainly used to support the mechanical rotating body and reduce the friction coefficient during its motion process. Textile machine bearings have good wear resistance and fatigue resistance to ensure the efficient operation of the textile machine.

The textile machine bearing is an outer ring with a stop ring on the outer diameter, with two sides with seal rings and with mounted tapered liners, locking washers, and accessories. Textile machine bearings are mainly used to withstand radial and axial combined loads mainly based on radial loads. In the process of installation and use, it has a good dustproof effect and can achieve a certain eccentric adjustment.

Textile machine bearings can allow the various components of the textile machine to operate smoothly and improve production efficiency. It generally has the characteristics of wear resistance, fatigue resistance, and high accuracy. This type of bearing usually needs to be able to withstand a certain radial and axial load, and have better accuracy and stability. In the textile process, it can ensure the smooth operation of each component, and improve the textile quality and production efficiency.

There are quite a variety of bearings used on textile machinery, such as deep groove ball bearings, self-aligning ball bearings, self-aligning roller bearings, and there are also needle roller bearings, fixed sets, etc., which are used by many textile enterprises.

Common types of textile machine bearings:

Deep groove ball bearing: It is the most representative rolling bearing with a wide range of uses, which can withstand radial load and axial load, and is suitable for high-speed rotation and occasions requiring low noise and low vibration.

Four-point contact ball bearing: It can withstand radial load and bidirectional axial load, and a single bearing can replace the angular contact ball bearing of the front combination or back combination, and is suitable for bearing pure axial load or synthetic load with a larger component of axial load.

Self-aligning ball bearing: It mainly withstands radial load, and while bearing radial load, it can also bear a small amount of axial load, but it is generally not suitable for bearing pure axial load.

Self-aligning roller bearing: It has better self-aligning performance and bearing capacity, and is mainly used to bear radial load, and can also bear a certain amount of axial load.

Needle roller bearing: It is composed of needle rollers and retainer components, with small size and light weight, and is suitable for occasions where the radial installation size is limited.

Fixed sleeve: It is composed of a fixed bushing, locking nut and locking washer, and is used to fix the tapered bore bearing on the cylindrical shaft.

In addition, there are also some other types of textile machine bearings, such as roller bearings, etc., which also play an important role in textile machinery. Different types of textile machine bearings have different characteristics and uses. The specific selection of which type of bearing requires a comprehensive consideration based on the working conditions of the textile machine, load requirements, speed, and other factors.

Our products with high precision and low noise, are widely used in metallurgy, mining,petroleum,chemical,coal, cement, paper,wind power, heavy machinery, port machinery and other industries. The company has independent import and export management rights. The products are sold all over the world, exported to more than fifty countries and regions such as South America,Western Europe, Southeast Asia, Central Asia, Africa and Australia.

The company always takes "solution, creation, value" as business philosophy, providing excellent bearing solutions for domestic and foreign customers. WGHB Bearings has passed ISO9001:2008 and ISO14001:2004. Through the implementation of strict quality standards, taking rigorous quality control measures to improve product quality and service quality, WGHB Bearings provides high quality products and services to consumers around the world.

Welcome all your OEM and ODM order. Your spefic purchase needs of selecting current product from our catalogue or seeking engineering assistance for your application will be directly submit to our customer service center, we will answer you ASAP.