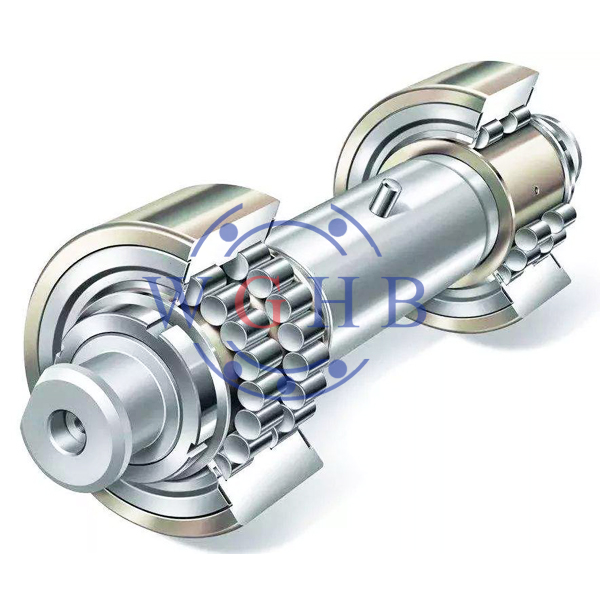

Machine tool spindle

Machine tool spindles have the characteristics of high precision, high speed, and high rigidity, which can ensure the machining accuracy and efficiency of the machine tool. During the operation of machine tools, the performance of the spindle directly affects the machining quality and production efficiency.

Product Description

Complete models

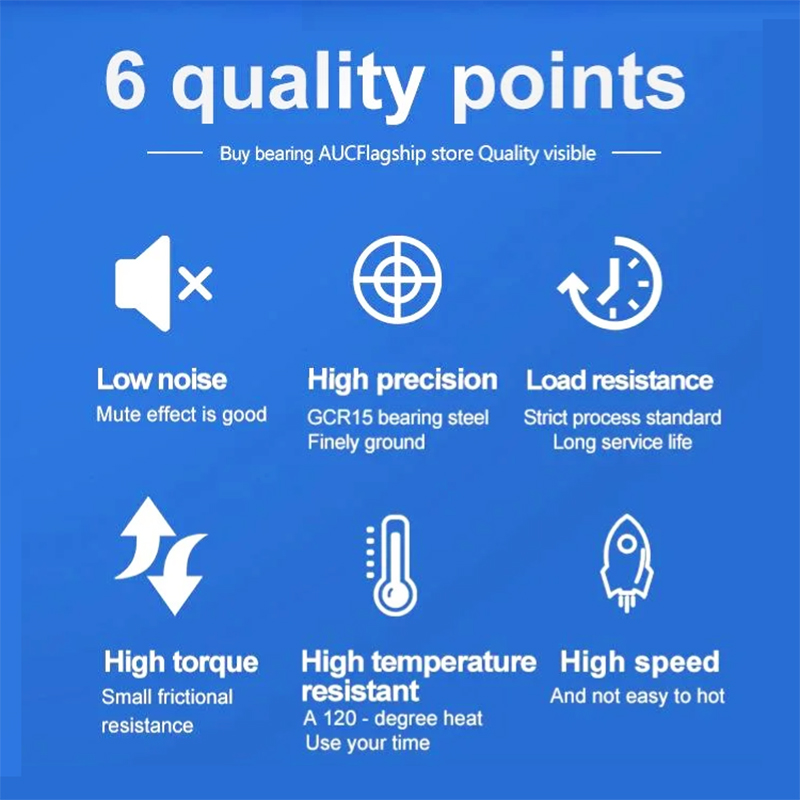

Quality assurance

The spindle of a machine tool is an important component of the machine tool, which undertakes the key task of driving the rotation of cutting tools or workpieces. With the continuous development of technology, the technology of machine tool spindles is also constantly advancing. The application of new materials and advanced manufacturing processes has further improved the performance of spindles.

Machine tool spindles have the characteristics of high precision, high speed, and high rigidity, which can ensure the machining accuracy and efficiency of the machine tool. During the operation of machine tools, the performance of the spindle directly affects the machining quality and production efficiency.

The commonly used method to reduce the working temperature of bearings is lubricating oil. There are two lubrication methods: oil gas lubrication and oil liquid circulation lubrication. When using these two methods, pay attention to the following points:

1. When using oil circulation lubrication, it is necessary to ensure that the oil level in the constant temperature oil tank of the spindle is sufficient.

2. The oil gas lubrication method is exactly the opposite of oil circulation lubrication, as it only needs to fill 10% of the bearing space capacity.

The advantage of cyclic lubrication is that it can reduce friction and heat generation while meeting lubrication requirements, and can also absorb some of the heat from the spindle components. There are also two types of lubrication for the spindle: oil mist lubrication and spray lubrication.

The common faults of machine tool spindles include the following

1. Spindle heating: It may be due to poor lubrication, bearing wear, and other reasons.

2. Spindle vibration: It may be due to insufficient bearing accuracy, improper installation, etc.

3. Spindle noise: It may be due to bearing damage, loose parts, etc.

4. Decreased spindle accuracy: may be caused by wear, deformation, etc.